SepticJohn - A Wastewater Incinerator System

Pickup available at 6148 Getty Dr

Usually ready in 24 hours

SepticJohn Sizing Chart

The size of SepticJohn System and Waste Tank depends on your Local Regulations. But as a reference, you can find a List below that can be used as a guideline. Note: Your local authorities may require different sizing.

Full Time Residential:

1 Bedroom: WC48

2 Bedrooms: WC64

3 Bedrooms: WC64

4: Bedrooms: WC64+WC48

Cabin / Office Dwellings; Not Full Time Residential:

1 Bedroom Toilets; Only (2 People): WC5

1 Bedroom/Office; All Wastewater (2 People): WC32/WC48

2 Bedrooms/Offices; Toilets Only (4 People): WC32

2 Bedrooms/Offices; All Wastewater (4 People): WC64

Residential Wastewater Incinerator: Total Treatment Solution

In today's society there are more and more regulations for installing septic tanks. Due to various reasons, such as property doesn't perc, water table is too high, rocky ground, old septic tank is failing, or it is just not practical/cost efficient to install a new septic system.

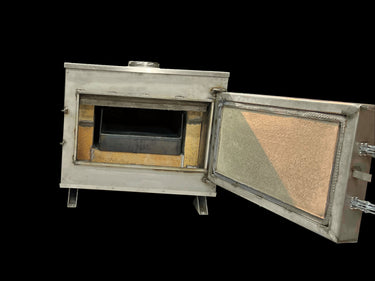

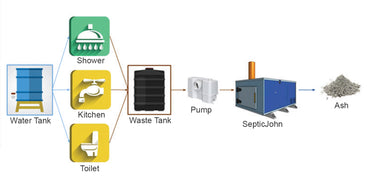

In these situations a septic alternative is required and this is where Ecojohn can help. Ecojohn has developed a new sewage incinerator system that evaporate all sewage (black and grey water) into a small amount of sterile ash. The ash is sterile and can easily be disposed off.

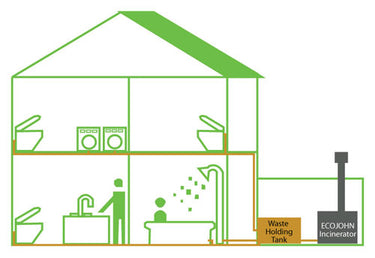

The SepticJohn systems operate with standard low flush toilets and fixtures, and the incinerator can be connected to existing installations. All wastewater gets plumbed to a holding tank in or above ground, and from there the waste gets pumped into the SepticJohn incinerator when called for.

These systems are controlled by an advanced PLC control system and Ecojohn offers remote monitoring service for customers who wants that extra layer of support.

One of the many advantages of these systems is the ease of installation. Basically, the entire system can be installed very quickly without any big mound or leach lines. If you have an existing holding tank, it is possible to leave that and simply hook up the incinerator with pump and ultrasonic level sensor.

The SepticJohn product line has systems that can process up to 300 gal/day. They can also be scaled if larger processing volume per day is required.

MODELS:

WC5 / WC32 / WC48 / WC64

Current Estimated Delivery Time:

6 - 8 Weeks

Small Footprint. Quick Install.

SepticJohn can operate with a standard in-ground single or dual chamber tanks. The incinerator needs to be protected from weather (rain, snow etc.); a standard 8x10ft building or shed is a perfect area to house the unit.

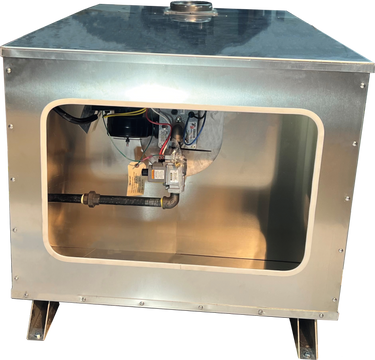

Above ground tank option.

If the soil is bad or if you simply can't install an in-ground tank, an above ground tank is another option. The wastewater gets transferred to the above ground tank by a transfer pump or gravity.

Real Estate Investment Opportunities. Fast ROI.

Invest with Confidence.

Whether you’re a developer, architect, engineer, or a lakeside property owner, installing a traditional septic system can be challenging. SepticJohn Systems offer the perfect alternative for difficult lots, providing an efficient and reliable solution. Reach out to our team to discuss your project today!